National Institute Of Materials Physics - Romania

Complex Heterostructures and Multifunctional Materials

Facilities and Services

Structural characterization by near infrared (NIR), infrared (midIR) and far infrared (farIR) Fourier transform infrared (FTIR) spectrometry platform from JASCO, encompassing the 12000 – 50 cm–1 spectral range

ViewMicrowave dielectric materials and devices testing laboratory, including:

ViewSolar cells testing laboratory, with two NEWPORT LED solar simulators (aperture 50 mm × 50 mm), one system for measuring the Quantum Efficiency/IPCE, and accessories.

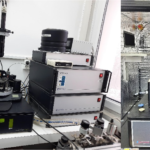

ViewSurface investigation by scanning probe microscopy (SPM) in contact or non-contact mode with piezoelectric (PFM), magnetic (MFM) or conductive (C-AFM) response: NT-MDT NTEGRA system (left) and Asylum MFP 3D SA (right).

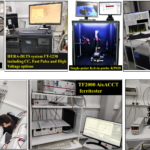

ViewElectrical measurements laboratory including: a tpt HB05 wire bonding machine, 2 LAKE SHORE cryo-probers for electrical measurements in the temperature range of 10 K – 400 K; one with vertical magnetic field up to 2.5 T, and one with horizontal magnetic field up to 1.5 T, each with at least 3 micro-manipulated arms with contact […]

ViewX-ray diffraction systems (i) for thin films analysis – Rigaku SmartLab 3 kW (2017) and Bruker D8 Advance (2006) from room-temperature to 1100 °C) and (ii) for powders – Anton Paar XRDynamic (2022) and Bruker D8 Advance (2007), from -190 ° to 600 °C. Structural characterization, allowing identification of crystalline phases, crystalline strain, quality of […]

ViewCeramic materials 3D printing laboratory, equipped with a NORDSON EFD, EV series, robocasting (direct ink writing) printing system, with Ultimus V dispenser (Fig. 1); an ANTON PARR MCR302e modular rheometer (Fig. 2); and a THINKY ARE-250 ceramic mixing & degassing machine.

ViewChemistry laboratories for the preparation of powders, thin films and bulk materials by chemical (wet) methods, equipped with high-temperature annealing furnaces; spin-coating and doctor-blade systems; glove-boxes; fume hoods; aggregate mills, weighing scales; glassware; etc (e.g., see below).

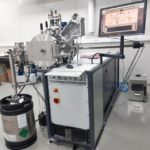

ViewMulti-cathode radio-frequency (RF), direct current (DC) and pulsed direct current (p-DC) Magnetron Sputtering (MS) systems with various facilities: bias, etching and heating (up to 800 °C) of substrates; vacuum load-lock for sample transfer; vacuum systems (down to ~10-6 Pa); computerized control and process automation. The latest MS equipment, AJA PHASE II J, purchased in 2016, […]

ViewSURFACE systems+technology GmbH & Co. KG hybrid system for thin films synthesis from temperature-sensitive materials by (i) Matrix Assisted Pulsed Laser Deposition (MAPLE) and (ii) PLD, constituted of: a deposition chamber with in-situ freezing facilities for targets (e.g., frozen suspensions of organic materials or inorganic nanoparticles in a support matrix); a KrF excimer laser with […]

ViewCopyright © 2025 National Institute of Materials Physics. All Rights Reserved