Innovative nanocarbon-based electrochemical monitoring of female hormones

Project Leader for NIMP: Dr. Victor DICULESCU

Project ID: 135 from 01/09/2025 (ERANET-HerAqua)

Project Type: ERA-NET

Funded by: Executive Agency for Higher Education, Research, Development and Innovation Funding (UEFISCDI)

Project Status: In progress

Start Date: September, 2025

End Date: August, 2028

The HerAqua project develops an innovative nanocarbon-based electrochemical microfluidic device for the continuous monitoring of female hormones in both artificial body fluids and environmental waters. Hormonal imbalance affects women across reproductive, menopausal, and pathological stages, while excreted hormones act as endocrine disruptors in the environment. Current methods—mainly LC-MS and immunoassays—are expensive, slow, and non-portable.

HerAqua proposes an integrated system based on MXene and carbon quantum dot (CQD) nanostructures, decorated with gold nanoparticles and functionalized with aptamers or antibodies, enabling selective and sensitive hormone detection. The project develops green, eco-friendly synthesis routes using natural deep eutectic solvents to minimize environmental impact. The end result is a laboratory-scale demonstrator (TRL 5) capable of multi-hormone detection with high sensitivity, short response time, and minimal sample volume, suitable for point-of-care and environmental monitoring applications.

HerAqua defines three main objectives, supported by several scientific sub-objectives.

Objective 1 — Develop nanocarbon-based electrodes. Design and synthesize MXene and CQD nanostructures using green deep eutectic solvents and electrochemical routes. These materials will be combined and decorated with Au nanoparticles to produce high-conductivity, high-surface-area electrode interfaces optimized for hormone detection. Expected results: scalable, safer synthesis routes, improved electrochemical performance, and reduced environmental footprint.

Objective 2 — Create high-selectivity (bio)sensors for hormone detection. Functionalize nanostructured electrodes with aptamers, antibodies, and enzymes targeting estrogen, progesterone, FSH, LH, TSH, and thyroxine. Develop optimized electrochemical detection protocols (DPV, EIS, CV). Expected results: detection limits down to nanomolar/picomolar range; enhanced selectivity and stability; simultaneous multi-hormone detection in complex matrices.

Objective 3 — Build and integrate a microfluidic device for continuous monitoring. Develop a microfluidic platform embedding the prepared (bio)sensors for real-time, continuous measurements in flow. Validate the device with synthetic body fluids and environmental water samples from rural and urban sources. Expected results: laboratory demonstrator at TRL 5; portable, low-cost sensing platform capable of multidetection; stable operation over multiple cycles.

The HerAqua consortium is international, intercontinental, and strategically balanced between research institutions and industry, covering all required competencies from materials synthesis to device engineering and validation.

Coordinator – Institute of Fluid-Flow Machinery, Polish Academy of Sciences (Poland)

Expertise in electrochemistry, carbon nanostructures, biosensors, and device integration. Leads project management, synthesis development, and biosensor functionalization.

Partner 2 – Universidade de São Paulo (Brazil)

Specialized in nanomaterials synthesis (MXene, CQDs), electrochemical characterization, and green chemistry approaches. Leads WP2 on nanocarbon electrode development.

Partner 3 – National Institute of Materials Physics (Romania)

Expert in microfluidics, theoretical modeling, and advanced diagnostics. Responsible for testing and validating the integrated microfluidic device with real water and synthetic body fluids. Supports sensor characterization and device optimization.

At NIMP, The project is carried out by the group of Lab. 10. Functional Nanostructures.

Partner 4 – MICRUX FLUIDIC S.L. (Spain)

Industrial partner providing commercial experience in microfluidic architectures, electrode printing, and miniaturized electrochemical platforms. Leads WP4 (device construction) and supports exploitation and LCA, bridging research and commercialization.

Phase 1 Report

The key findings of Phase 1 (2025) of the HerAqua project, focused on assessing 3D printing accuracy and conducting preliminary numerical analysis for the design of a microfluidic device. The work investigated fabrication tolerances, geometric distortions, and hydrodynamic behavior relevant to microfluidic performance.

3D Printing Accuracy. Calibration geometries containing circular holes (1.0–2.0 mm) and linear features (0.02–1.80 mm width) were printed using an Elegoo Saturn 4 Ultra 16k printer. Microscopy analysis revealed systematic deviations from CAD geometries. Holes exhibited tapering due to resin pooling and variable curing conditions, with inner diameters consistently smaller than outer ones. Line structures showed width-dependent distortions: narrow lines broadened due to lateral overcuring, while larger widths were slightly underestimated. Corner fidelity was also limited, with rounded terminations especially pronounced for small features. These findings highlight scale-dependent fabrication limits and guide tolerance adjustments in future CAD designs.

Microfluidic Device Design Considerations. A preliminary CAD architecture was developed featuring two inlets, a mixing region, and a detection chamber intended for electrode placement. Numerical simulations will optimize inlet widths, lengths, bifurcation angle, and mixing region geometry to ensure symmetric flow, adequate residence time, and efficient analyte homogenization prior to detection.

Electrode configurations evaluated include parallel cylindrical wires, perpendicular wires, and planar thin-film electrodes. Geometric constraints, flow perturbation, and fabrication feasibility differ among these designs, with planar electrodes offering minimal obstruction but requiring additional processing steps.

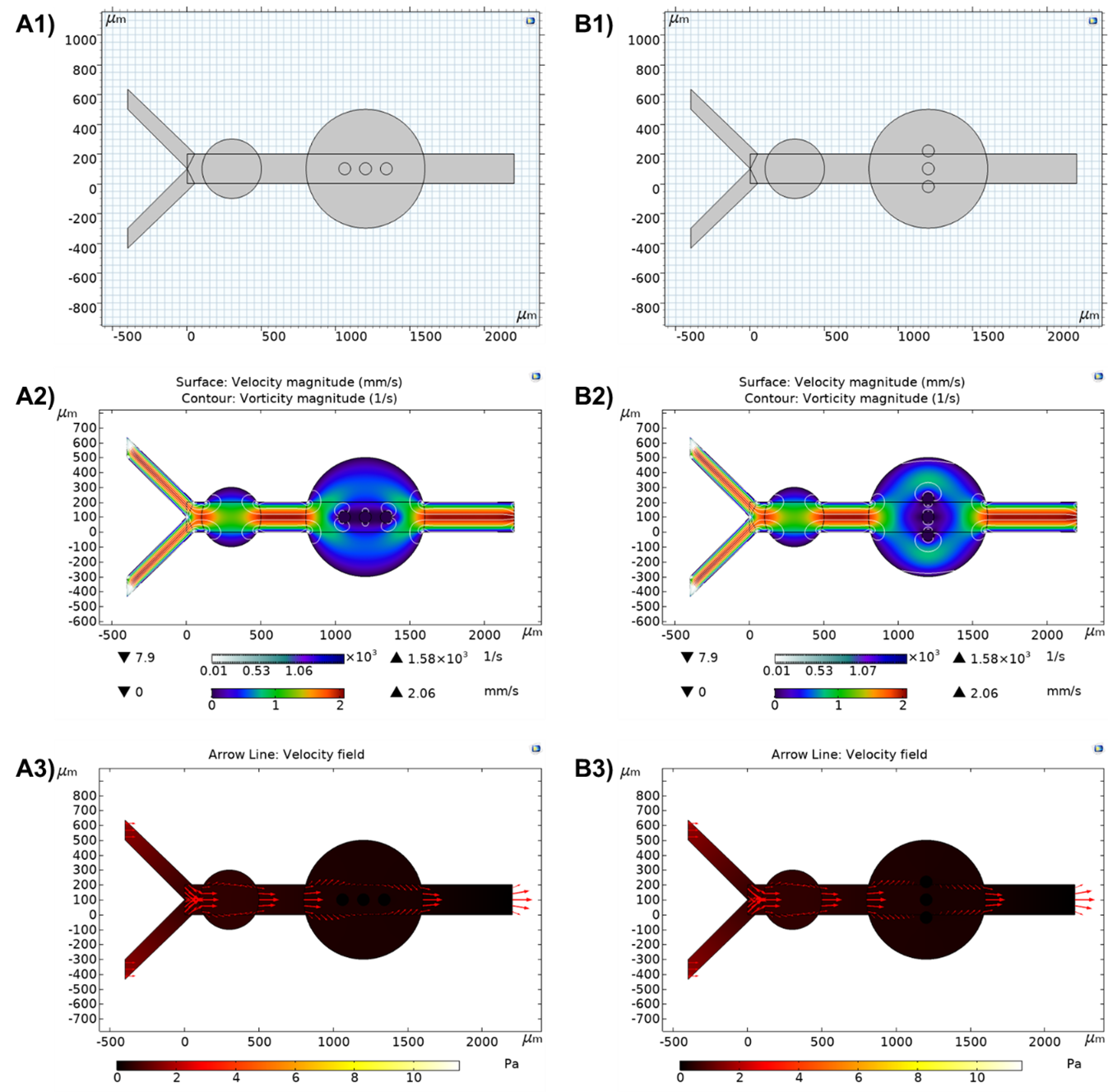

Numerical Flow Analysis. Simulations of laminar flow around parallel vs. perpendicular wire electrodes demonstrate substantial differences. Parallel electrodes maintain smooth streamlines with minimal vorticity and low pressure variation, providing a stable hydrodynamic environment for electrochemical detection. Perpendicular electrodes cause significant disturbances, including recirculation zones and asymmetric velocity fields. While these may enhance mixing, they introduce variability in transport and signal reproducibility.

Numerical analysis of fluid flow within the microfluidic device, performed for A) parallel and B) perpendicular electrode placement against the main flow. A2), B2) Velocity and vorticity distribution and A3), B3) pressure distribution along the channel.

Conclusion. The combined experimental and numerical results establish critical geometric tolerances and flow considerations for the final microfluidic device. Systematic fabrication deviations provide a predictable basis for design compensation, while flow analysis supports the selection of parallel electrodes for stable electrochemical response.

At NIMP, the project involve training of two PhD students and two Post-doc Researchers in biosensing technologies and engineering.

PROJECTS/ NATIONAL PROJECTS

Copyright © 2026 National Institute of Materials Physics. All Rights Reserved