2D metallic carbide as active and selective catalysts for direct oxidation of CH4

Project Director: Dr. Mihaela FLOREA

The project nature, which is at the frontier between catalysis and materials science, is a good opportunity for the researchers and PhD students to be trained in different areas necessary to conduct modern research in chemistry.

Relevant expertise: The team’s competences are in the field of chemistry, catalysis and materials physics.

Added value: A deep understanding through characterization of the new materials; recommendation of ways to make the materials more competitive.

The 2DreaM team is the following:

Mihaeala Florea, PhD, habil. - principal investigator, specialized in material synthesis and surface characterization, in charge with the management and dissemination tasks

Members:

Florentina Neatu, PhD, specialist in material synthesis, good experience working with characterization techniques; dissemination

Stefan Neatu, PhD, with competence in materials synthesis and characterization and dissemination.

Anca Mirea- PhD, postdoc, in charge with electron microscopy studies characterization, dissemination.

Toton Haldar- PhD, postdoc, in charge with methane oxidation reaction study, stability and dissemination.

Mihaela M. Trandafir, PhD, postdoc, in charge with samples preparation, dissemination.

Iulia M. Chirica, PhD student, in charge with RAMAN and UV-vis characterization, dissemination.

Team of the project!

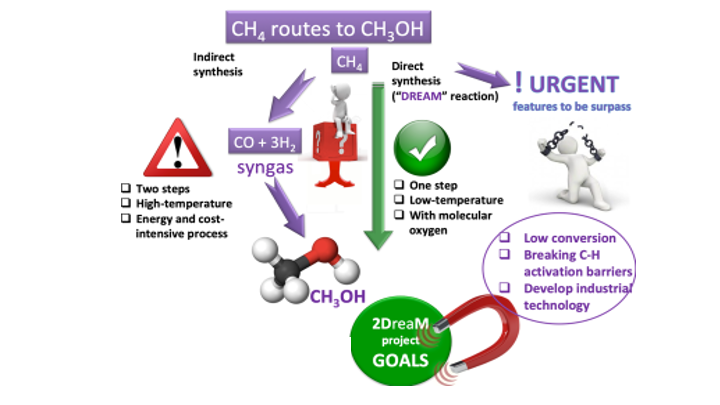

Selective activation of C–H bonds in direct oxidation of methane (DOM) is still an unsolved problem, owing to methane inert nature and less thermodynamically stable oxidation products. Since CH4 transformations are based on high-temperature (>700 °C), expensive energy and cost technologies, new generation of catalysts is required to convert CH4 and O2 directly into valuable chemicals in high yields, at lower temperatures (200–400 °C).

The main driving force of 2DreaM is to elaborate a new generation of catalytic systems based on 2D carbide-nitride materials for DOM to valuable compounds, with high efficiencies and under environmentally friendly conditions.

Classical heterogeneous systems involve a metal deposited on an oxidic support: M/MOx, where the metal’s ability to chemisorb hydrogen is impeded by the oxide migration to the surface. Starting from this approach and being aware of the essential required properties for direct CH4 transformation, we propose a creative concept: an “upside down” catalytic system in which small entities of metal oxide are deposited on a 2D “metallic” material: MOx/M. Our strategy is to use as support transition metals (TM) 2D carbide materials, able to activate the C–H bond, decorated with different MOx . This way, the highly tunable “metallic” surfaces provide an increased number of active sites to chemisorb and labilise the C–H bond, promoting its selective oxidation by MOx species. Such materials have never been used as heterogeneous catalysts in DOM, that’s why the 2DreaM challenge is immense, but so is the reward.

FIRST STAGE 2021

During the first stage of the project, samples containing different amount of VOx were prepared. They were supported using different preparation methods. The X-ray diffraction and XPS analysis indicate the successful deposition of VOx on the MAX phase.

SECOND STAGE 2022

New heterogeneous catalysts, MOx (M=V, Cu, Fe) deposited on metal carbides (Ti3SiC3 and Ti3C2), were successfully prepared during this stage. X-ray diffraction data ans SEM analysis confirmed the deposition of the MOx on the support surfaces. Also, the preliminary catalytic results have been obtained in a continuous flow fixed bed reactor system for the synthesized materials. No methane conversion was observed for V2O5/Ti3SiC2 below 400 ˚C, while on the Cu-based catalysts, we transformed CH4 above 300 ˚C. Good selectivities in formaldehyde, around 50% were obtained in all cases but at low CH4 conversions (~6%), while the methanol production was obtained in very small amounts when the ratio between the reactants was different from the stoichiometric one.

According to the working plan, in this stage, we envisaged designing new heterogeneous catalysts, MOx deposited on 2D and 3D metal carbides. X-ray diffraction data and SEM analysis confirmed the deposition of the MOx on the support surfaces. Also, the preliminary catalytic results have been obtained in a continuous flow fixed bed reactor system for the synthesized materials. Good selectivities in formaldehyde, around 50% were obtained in all cases but at low CH4 conversions (~6%), while the methanol production was obtained in very small amounts when the ratio between the reactants was different from the stoichiometric one.

In this year our research team has been awarded twice with beam time at PSI Synchrotron, where we performed experiments in AP-XPS in order to determine the surface dynamic of our materials.

THIRD STAGE 2023zxCx

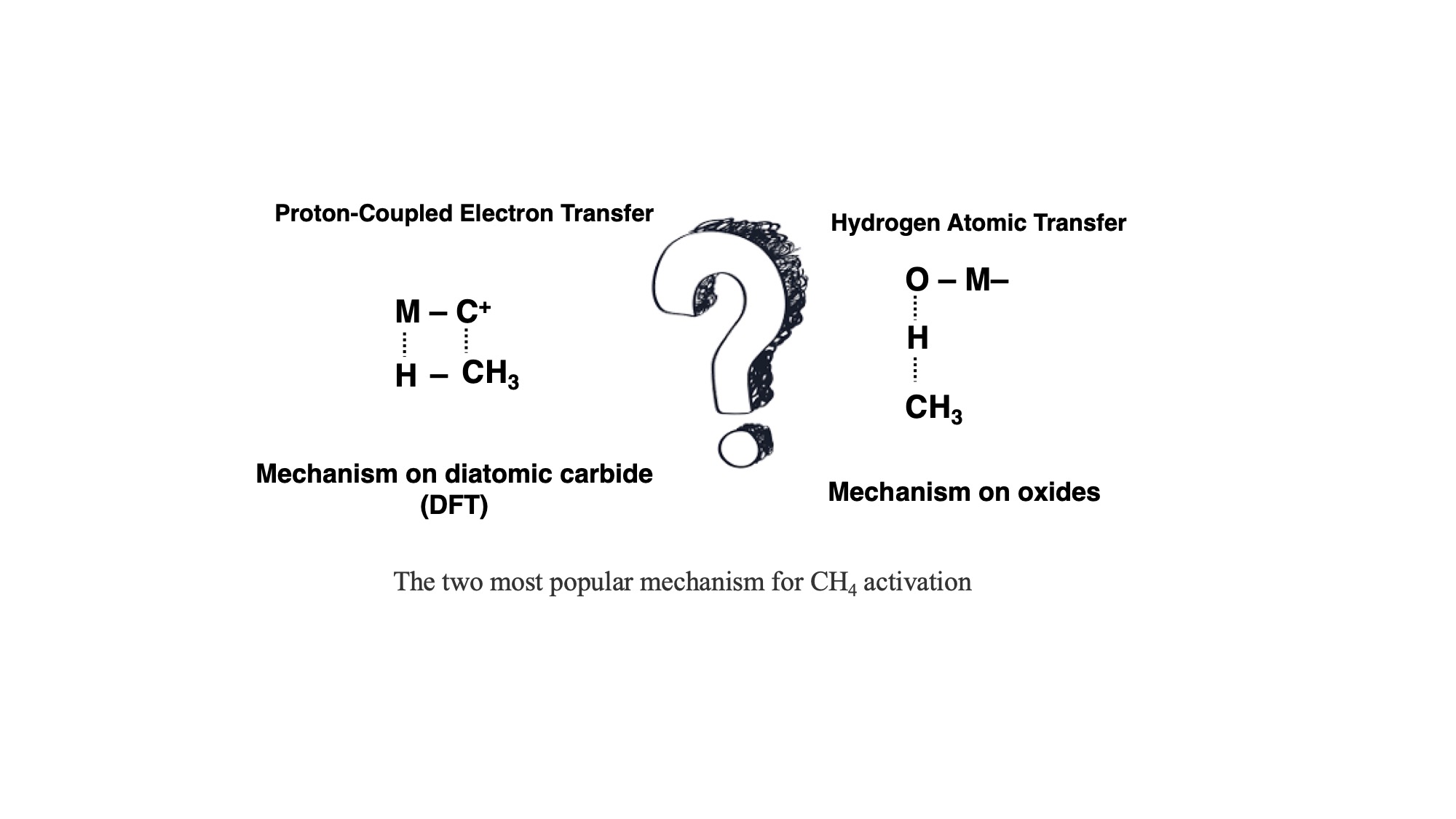

Consistent with the initial predictions, the MXene surface species can play an important role and the results revealed that methoxy groups (CH3O)—precursor of methanol—formed on the catalytic surface in the presence of CH4/O2 and CH4/O2/H2O mixtures. Most probably the formation of the CH3O- takes place on the Ti-O species, so we suppose that the formation of methanol occurs by Hydrogen atomic transfer. However, more studies are needed to confirm this behavior. H2O has an important role in the generation of OH species that are necessary for methanol formation/desorption.

The most important outcome of this project is that we have succeeded to study the dynamics of the surface and structural changes that these 2D metal carbides (MXenes based catalysts) undergo during catalysis and lead to efficient catalyst function under steady-state O2 and/or CH4 environment at different temperatures (between room temperature and 350 ˚C).

The mechanisms of reactions in which an electron and a proton are transferred in a single step can be divided into two distinct classes, hydrogen atom transfer (HAT) and proton-coupled electron transfer (PCET). The two mechanisms are depicted in the next Figure.

Internships for students from the Faculty of Chemistry, University of Bucharest were organised within the project topic.

Participation in a project, CHEMPOET, aiming at spreading science, especially chemistry in high schools.

More information can be found on http://chempoet.mariusmatache.ro

1. Articles

- A comparative overview of MXenes and metal oxides in clean energy production through photocatalysis; Mahesh M. Nair, Alexandra C. Iacoban, Florentina Neațu, Mihaela Florea, and Ștefan Neațu, submitted to Journal of Materials Chemistry A, (2023), 11, 12559-12592 2023, DOI: 10.1039/d2ta08983a, (IF=12);

- Ultra-stable, 1D TiO2 Lepidocrocite for Photocatalytic Hydrogen Production in Water-Methanol Mixtures, Hussein O. Badr, Varun Natu, Ștefan Neațu, Florentina Neațu,3 Andrei Kuncser, Arpad M. Rostas, Matthew Racey, Michel W. Barsoum and Mihaela Florea, Matter, 6, (2023) 2853–2869, DOI: 10.1016/j.matt.2023.05.026, (IF= 19)

- “Chapter 5.01 Application of Hydrogen in Light alcohols production”, CRC Press/Taylor & Francis (2023), "Handbook of Hydrogen Production and Applications", Alexandra C. Iacoban, Toton Haldar, Mihaela Florea, Editors: Prof. M.R. Rahimpour, Dr. M. A. Makarem and Ms. P. Kiani- under publication.

2. Conferences

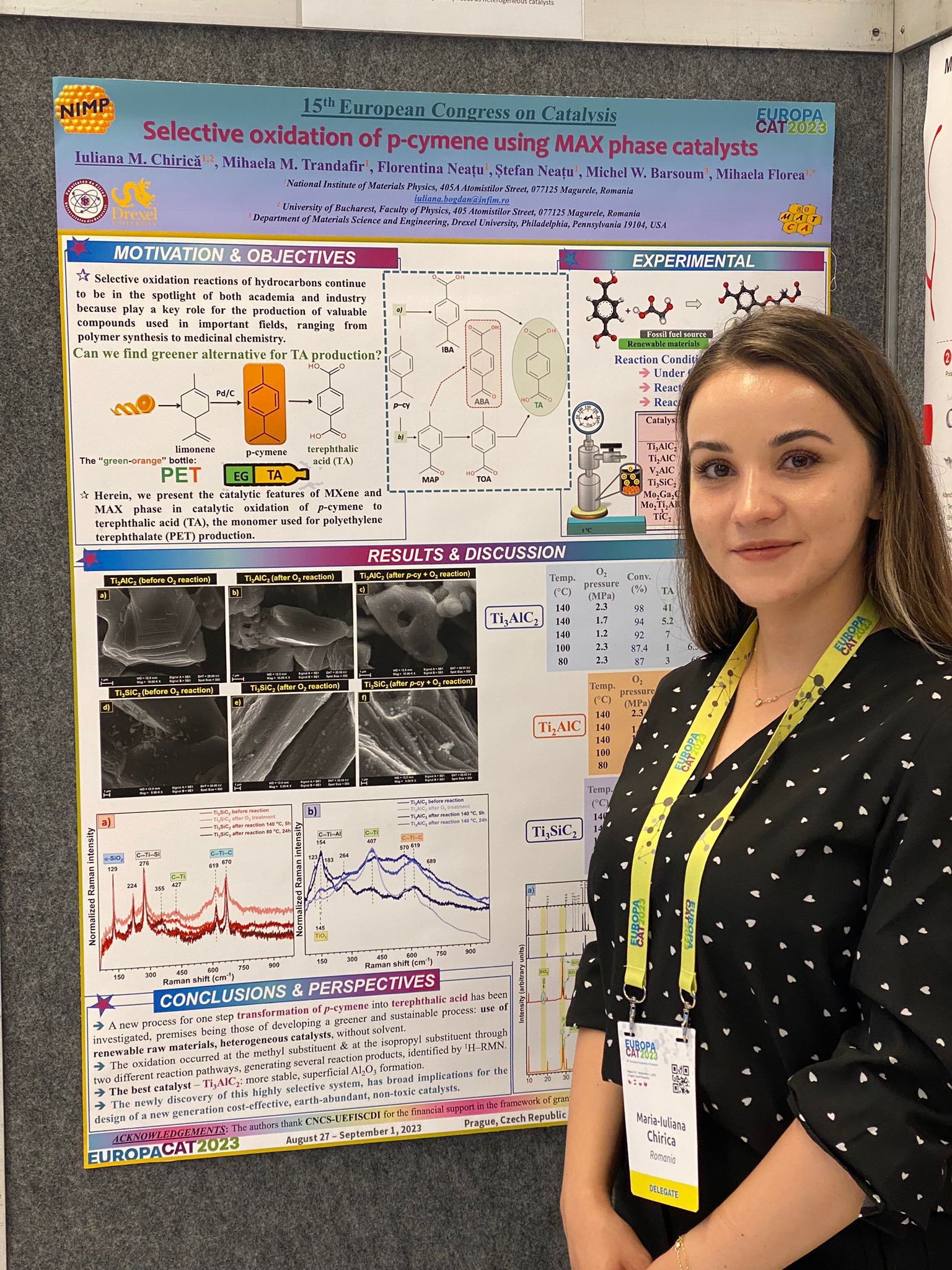

2.1. Selective oxidation of p-cymene using MAX Phase catalysts, Iuliana M. Chirica, Mihaela M. Trandafir, Florentina Neatu, Stefan Neatu, Michel W. Barsoum, Mihaela Florea, Catalysis Science & Technology Symposium 2021, 16-17 November, poster presentation - BEST POSTER price

2.2. Unprecedented chemoselective behaviour of MAX phase in functionalized nitroarene hydrogenation, Iuliana M. Chirica, Mihaela M. Trandafir, Florentina Neatu, Stefan Neatu, Andrei Kuncser, Varun Natu, Michel W. Barsoum, Mihaela Florea, 8th EuChemS Congress 2022, 27 August 2022 - 3 September 2022, Lisabone, Portugal, oral presentation

2.3. MXene and MAX phase as catalysts for selective oxidation reactions, Iuliana M. Chirica, Mihaela M. Trandafir, Florentina Neațu, Ștefan Neațu, Michel W. Barsoum, Mihaela Florea, 2nd international MXene conference at Drexel University, August 1-3, 2022, Philadelphia, USA, poster presenatation.

2.4. Dynamic surfaces of MAX phase and MXene in catalytic processes, Florentina Neatu, Stefan Neatu, Luca Artiglia, Marius Husanu, Michel Barsoum, Mihaela Florea, 9th Annual Ambient Pressure X-ray Photoelectron Spectroscopy Workhop, 6-9 December, PSI, Swiss, oral presentation

2.5. Revealing catalytic feature of MAX phase and MXene, Mihaela Florea, SMART DIASPORA 2023, Timisoara, 10-13 April 2023, invited lecture

2.6. 2D acid catalysts for depolymerizationn reaction, Florentina Neatu, SMART DIASPORA 2023, Timisoara, 10-13 April 2023, invited lecture

2.7. Selective oxidation reaction using MAX phases as heterogeneous catalysts, M.-I. Chirica, M.-M. Trandafir, A. G. Mirea, F. Neaţu, Ş. Neaţu, M. Barsoum, M. Florea, EuropaCat 2023, 27.08-01.09.2023, Praga, Cehia, Poster

2.8. Catalytic PET depolymerization by hydrolysis using sulfonated 2D MXenes, M.-I. Chirica, Ş. Neaţu, A. G. Mirea, M. Barsoum, M. Florea, F. Neaţu, EuropaCat 2023, 27.08-01.09.2023, Praga, Cehia, Prezentare orala.

2.9. MAX phase as an efficient heterogeneous catalyst for nitrostyrene chemoselective hydrogenation, M.-I. Chirica, M.-M. Trandafir, F. Neaţu, Ş. Neaţu, A. Kuncser, V. Natu, M. Barsoum M. Florea, EuropaCat 2023, 27.08-01.09.2023, Praga, Cehia, Prezentare orala.

2. 10 Catalytic behaviour and surface changes of MAX phases and MXenes, Alexandra C. Iacoban, Toton Haldar, Florentina Neatu, Stefan Neatu, Luca Artiglia, Michel Barsoum, Mihaela Florea, EuropaCat 2023, 27.08-01.09.2023, Praga, Cehia, Prezentare orala.

Dr. Mihaela Florea, mihaela.florea@infim.ro

Postal address: Atomistilor street, no. 405A, Magurele, 077125, Romania

PROJECTS/ NATIONAL PROJECTS

Copyright © 2026 National Institute of Materials Physics. All Rights Reserved