Compensated ferrimagnetic oxides for rapid magnetic switchers (FEMAGSWIT)

Project Director: Dr. Maria Cristina BARTHA

Project ID: 676 PED din 21/06/2022

(PN-III-P2-2.1-PED-2021-2007)

Project Director: Dr. Maria Cristina Bartha (Valsangiacom)

Project Type: National

Project Program: PED

Funded by: Romanian National Authority for Scientific Research, UEFISCDI

Contractor: National Institute of Materials Physics

Project Status: In progress

Start Date: 21 June, 2022

End Date: 21 June, 2024

Project summary:

The aim of this project was to obtain and validate an advanced material, namely a RE3Fe5O12 garnet structured oxide (RIG) with RE=Tb, Gd, Dy and Ho for future generations of electronic devices. The overall objective of the project was to select a material (demonstrator model) with magnetic properties suitable for applications in high performance spintronics, namely a magnetic switching device. The rare earth and iron garnets mentioned were obtained by two different processing methods, one of which, innovative and environmentally friendly, was used for the first time for the development of these materials. Functionality testing and validation was carried out in the laboratory, finally selecting Gd3Fe5O12 and Dy3Fe5O12 as demonstration materials. They have optimal structural, morphological and magnetic properties for magnetic switch applications.

Brief presentation of the project results:

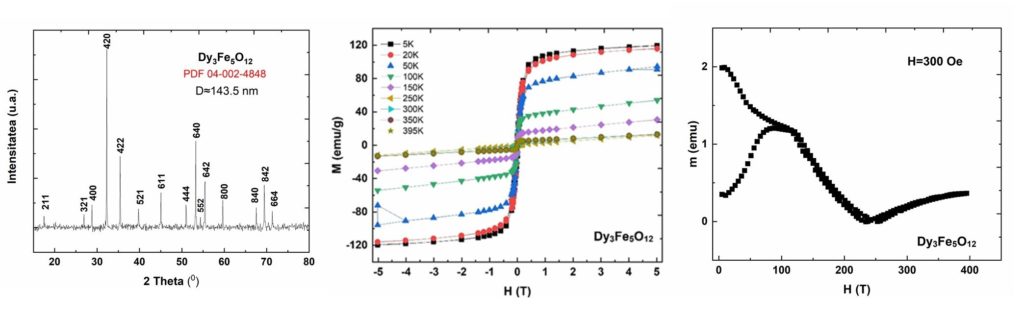

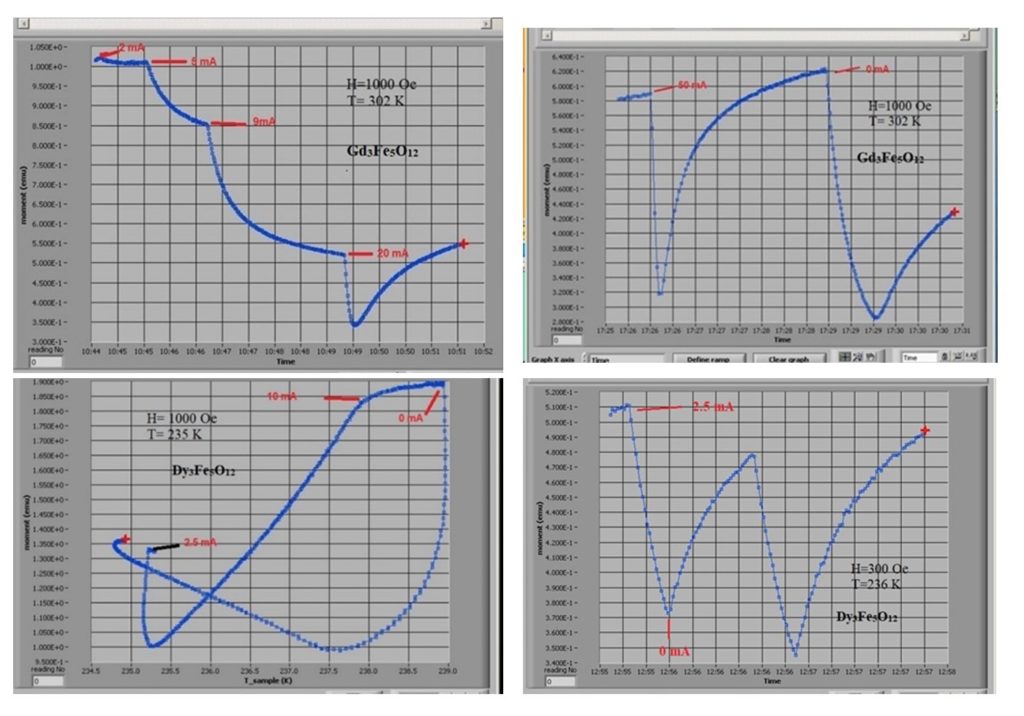

In this project were obtained oxide materials with garnet structure, such as Gd3Fe5O12, Tb3Fe5O12, Ho3Fe5O12, Dy3Fe5O12 with close structural and microstructural characteristics and/or with ideal stoichiometry depending on the processing technology and optimized magnetic properties with high practical potential (e.g. compensation temperatures close to and/or slightly above room temperature, high magnetic transition temperatures, magnetic behavior and coupling distribution favorable to different functionalities). Two of the materials have been selected as demonstration materials, namely Gd3Fe5O12 and Dy3Fe5O12 processed by innovative technologies that have optimal structural, microstructural and magnetic characteristics for the switching properties tested in the laboratory. Both materials present stoichiometric garnet phases in a proportion of more than 90 %, the rest being garnet phases with cationic inversions, but with insignificant influence on the magnetic properties. Dy3Fe5O12 processed by SPS was obtained 100% as stoichiometric phase. The functional characteristics were tested and validated in the laboratory, both materials showing variations in magnetization upon application of an electrical polarization. These were verified at different current intensities, from 2 mA and 50 mA and temperatures around the compensation ones. The switching effect is more consistent at currents above 20 mA, the sample being in the form of a ground body.

Figure 1. Selection of properties obtained on sintered Dy3Fe5O12 SPS.

Figure 2. Variation of magnetization with time and temperature when

applying/removing an electric polarization (indexed by the current read) with varying intensities.

Dr. Maria Cristina Bartha (Project Director)

Dr. Victor Kuncser

Dr. Petre Badica

Dr. Cezar Comanescu

Dr. Alina Crisan

Dr. Andrei Kuncser

Dr. Mihai Alexandru Grigoroscuta

Ph.D Student Andrei Alexandru-Dinu

MSc. Student Ani Sergentu

Stage I summary:

In this first stage of the project, oxide precursor nanopulbers with garnet structure of RE3Fe5O12 type were prepared, where RE= Gd, Tb, Dy and Ho and were complexly characterized both from a structural and morphological point of view. In order to obtain the materials, two processing methods were used (one of them being used for the first time on this type of compounds). At the same time, several studies related to the evolution of properties have been carried out, at this stage, the emphasis being placed on the magnetic properties of oxides with garnet structure obtained by the classical method.

Stage II summary:

The second stage of the experimental demonstration project aimed at obtaining bulks with garnet structure of RE3Fe5O12, where RE = Gd, Tb, Dy and Ho by the Spark Plasma Sintering method and their complex structural and microstructural characterization and the investigation of magnetic properties. The SPS method allows to perform sintering heat treatments at high temperatures (up to 2400 °C) using high heating and/or cooling rates (up to 500 °C/min). Among the advantages of using this method are: obtaining bulks with high density (more than 90% of the theoretical density of the processed material), maintaining low particle sizes due to the rapidity of the heat treatment, obtaining microstructural characteristics superior to those obtained by classical sintering treatments, etc. The structural and microstructural investigation of the materials reveals two phases with garnet structure: a stoichiometric phase of (Gd3(Feoct+tet)5O12) type which is the majority (≥ 90%), in some of the samples it is even the only phase, and a phase showing cationic and/or oxygen stoichiometric defects of the (Gd)3-x[(Fe2-x)oct(Fe3-x)tet]O12-x type. The coexistence of the two phases significantly influences the properties, especially the magnetic properties which are extremely sensitive to the local changes involving cation distribution and/or defects generated by the variation of oxygen stoichiometry. Therefore, the obtained materials show a distribution of magnetic couplings favoring the achievement of properties with varied application potential. These will be explored in the final stage of the project, the aim being to select demonstrator material with optimal properties for the proposed applications. In addition, some studies on the switching properties of the selected material have been carried out.

Stage III summary:

Stage number 3 of the project implementation plan focused on the centralization, analysis and dissemination of the results obtained during the whole project, as well as the management part which involved communication, leadership, team coordination, risk mitigation, organizational and administrative aspects, training and mentoring etc. It should be mentioned that this stage spanned the whole 24 months of the project, with dissemination of results and project management being carried out throughout the implementation period. From the point of view of the practical exploitation of the Gd3Fe5O12, Tb3Fe5O12, Ho3Fe5O12, Dy3Fe5O12 materials obtained during the project, as well as of the proposed innovative processing technologies, the experimental data collected and validated during the project, the theoretical studies describing in detail the structural characteristics of the materials, the technological processing steps and parameters, as well as the methodology for testing the functionality of these materials are relevant elements for the achievement of the objectives of the implementation plan. From the scientific point of view, the dissemination of the results was done in ISI journals (e.g. Ceramics International, Scientific Reports etc.) and in relevant conferences in the field (e.g. International Conference on the Applications of the Mössbauer Effect -ICAME, 8th International Conference on Superconductivity and Magnetism etc.). Two patent applications have been registered at OSIM and a silver medal was obtained at EUROINVENT 2024.

Part of the results obtained within the project will constitute a chapter of the PhD thesis entitled "Methods for the preparation and complex local characterization in functional nanostructured systems" which will be defended between September-October, 2024 at the Faculty of Physics of the University of Bucharest by Andrei Alexandru-Dinu under the coordination of CS1 Dr. Victor Kuncser (both being members of the project implementation team).

Web of Science articles - published or accepted:

- "Advance of Nanoparticles and Thin Films", Bogdana Borca and Cristina Bartha, Coatings 2022, 12(8), 1138; https://doi.org/10.3390/coatings12081138

- "Kinetics and the Effect of Thermal Treatments on the Martensitic Transformation and Magnetic Properties in Ni49Mn32Ga19 Ferromagnetic Shape Memory Ribbons", Tolea, F.; Popescu, B.; Bartha, C.; Enculescu, M.; Tolea, M.; Sofronie, M., Magnetochemistry 2023, 9, 7. https://doi.org/10.3390/magnetochemistry9010007.

- "Up-Conversion Luminescence and Magnetic Properties of Multifunctional Er3+/Yb3+-Doped SiO2-GdF3/LiGdF4 Glass Ceramics", Secu, C.; Bartha, C.; Radu, C.; Secu, M. Magnetochemistry 2023, 9, 11. https://doi.org/10.3390/magnetochemistry9010011.

- Synthesis of CoFe2O4 Through Wet Ferritization Method Using an Aqueous Extract of Eucalyptus Leaves, Gingasu D., Culita DC., Moreno JMC., Marinescu G., Bartha C., Oprea O.,Preda S., Chifiriuc MC., Popa M., Coatings 2023, 13(7), 1250; https://doi.org/10.3390/coatings13071250.

Articles under evaluation:

5.“Microstructure and coupling mechanisms in MnBi-FeSiB nanocomposites obtained by spark plasma sintering”, A. Alexandru-Dinu, C. Locovei, C. Bartha, M.A. Grigoroscuta, M. Burdusel, A. Kuncser, P. Palade, G. Schinteie, N. Iacob, Lu W., D. Batalu, P. Badica, V. Kuncser (Scientific Reports).

6."Crystallization processes of rare-earth doped GdF3 nanocrystals in silicate glass matrix: dimorphism and photoluminescence properties”, C. E. Secu, C. Bartha, C. Radu and M. Secu (Ceramic International).

Articles in preparation:

7. Complex structural characterization of Gd3Fe5O12 obtained by different routes”, Cristina Bartha, Claudiu Locoveia, Andrei Alexandru-Dinua, Cezar Comanescu, Mihai Grigoroscuta, Nicusor Iacob, Andrei Kuncser, Magda Galatanu, Aurel Leca, Petre Badica and Victor Kuncser will be send to Scripta Materialia.

International Conferences:

- Cristina Bartha, Andrei Alexandru Dinu, Cezar Comanescu, Simona Greculeasa, Nicusor Iacob, Aurel Leca, and Petre Badica, "Rare earth garnet of Gd3Fe5O12 type for future generation of electronic devices", 7th edition of the International Workshop Of Materials Physics, Recent Trends in Magnetism and Superconductivity, 31 of August- 2 of September, Magurele, 2022 ( poster ).

- Structural, Mössbauer Spectroscopy and Magnetic Investigations of Gd3Fe5O12 garnets obtained by different routes”, C. Bartha, C. Comanescu, M. Grigoroscuta, A. Alexandru-Dinu, P. Badica and V. Kuncser, International Conference on the Applications of the Mössbauer Effect -ICAME 2023, 3- 9 Septembrie 2023, Cartagena de Indias, Columbia (Oral presentation).

- Magnetic Properties of Rare Earth Iron Garnets Prepared by Two Synthesis Routes”, A. Alexandru-Dinu, C. Bartha, M. Grigoroscuta, C. Comanescu, V. Kuncser and P. Badica, 8th International Conference on Superconductivity and Magnetism, 4-11 Mai 2023, Ölüdeniz-Fethiye Turcia (Poster).

- Magnetic Oxide Ceramics for Spintronics Applications” C. Bartha, A. Alexandru-Dinu, M. Grigoroscuta, C. Comanescu and P. Badica, 8th International Conference on Superconductivity and Magnetism, 4-11 Mai 2023, Ölüdeniz-Fethiye Turcia (Poster).

- Bulk MgB2 and Rare Earth Iron Garnets Processed by Spark Plasma Sintering”, P. Badica, 8th International Conference on Superconductivity and Magnetism, 4-11 Mai 2023, Ölüdeniz-Fethiye Turcia (Oral presentation).

- Magnetic interactions and associated effects in rare-earth iron garnets processed by different routes”, Cristina Bartha et al. 8th International Conference on Superconductivity and Magnetism, 27 April-4 Mai 2024, Ölüdeniz-Fethiye Turcia (Oral presentation).

- "Process for obtaining oxide materials with garnet structure based on iron and rare earths", Cristina Bartha et al. E U R O I N V E N T , 16th European Exhibition of Creativity and Innovation Iasi, Romania, 6-8 June 2024 (poster).

Patent

"Process for obtaining oxide materials with garnet structure based on iron and rare earths and types of systems obtained, application no A/00200 din 25/04/2023 submitted to OSIM.

"Functional composite materials with garnet powder embedded in polymer matrix", patent application no. A/00324 dated 13/06/2024 filed with OSIM.

Maria Cristina Bartha (Valsangiacom), PhD in Physics

Senior Researcher II

Telephone: +40-(0)21-2418 146

Department: Magnetism and Superconductivity

Email: cristina.bartha@infim.ro

PROJECTS/ NATIONAL PROJECTS

Copyright © 2026 National Institute of Materials Physics. All Rights Reserved