Development of detectors based on volume absorbers for CO2 laser energy measurement

Project Director: Dr. Silviu POLOSAN

PROJECT EXECUTIVE SUMMARY (ENGLISH)

The project aims to expand the range of instruments for measuring the power of laser beams in various applications by applying innovative solutions regarding the volume absorbers, the detector’s geometry and its operating principle. The project focuses on analyzing viable solutions for measuring the energy of continuous-wave CO2 lasers using phosphate tellurite glasses as volume absorbers.

Briefly, the volume absorbers convert laser energy into heat energy through optical absorption. The heat transfer through the volume absorbers is measured at the backside using convenient thermocouples.

The superior properties of phosphate tellurite glasses, compared with the silicate glasses widely used as volume absorbers, make them more suitable as volume absorbers, including a lower specific heat for a temperature range below 500 C and higher thermal conductivity, together with higher absorbance in the infrared region and a shorter time for the heat transfer along the thickness of the volume absorbers.

a) A deeper understanding of the glass compositions over the main parameters used for the volume absorbers, such as: absorption coefficient, thermal conductivity, penetration depths and times for the heat transfer in the glass volume.

b) Designing the geometrical parameters of the volume absorbers, like thickness and densities.

c) Designing the matching geometry such as planar surfaces or wedge prisms.

d) The use of metal coatings for the electrodes (different metals and thicknesses)

e) The transformation of an energy meter into a power meter (keeping in mind the shorter time for the heat transfer).

f) With the help of a Bluetooth/Wi-Fi module, the recorded data will be transmitted to a computer, resulting in a CSV file, which is very often used in the storage of experimental information in scientific laboratories.

Coordinator - National Institute of Materials Physics - Romania

Partner- APEL LASER S.R.L.-Romania

NIMP

Dr Silviu Polosan- Project manager silv@infim.ro

Dr Iulia Corina Ciobotaru - Scientific Researcher III corina.ciobotaru@infim.ro

Dr Constantin Claudiu Ciobotaru - Scientific Researcher claudiu.ciobotaru@infim.ro

Dr Andrei Nitescu-PhD Student andrei.nitescu@infim.ro

Apel Laser srl

Radu Mihail Udrea-PhD Student at the Faculty of Physics, University of Bucharest

Mircea Udrea-Scientific researcher I

Summary of stage 1.

Preparing oxide materials, together with the design and realisation of the detector assembly.

Activity 1.1.Choosing metal oxides with absorbent properties.

Different types of absorbing glass were obtained by varying the heating, melting, casting, annealing and cooling parameters to test the influence of these parameters on their optical properties. Variation of some parameters, such as melting temperature, melt holding time, heating and cooling ramp, and casting temperature, can have adverse effects on absorbing glasses, especially on the absorption of radiation in the infrared range.

Activity 1.2. Mechanical processing of the obtained oxide glasses: cutting, grinding, electrode deposition, electrode adhesion

To be used as an absorbing medium for CO2 laser radiation, we chose to cut the samples into discs 14 mm in diameter and 1.2-1.5 mm thick. The cutting technique is based on the use of diamond discs (due to the high hardness of these oxide glasses) with stamped dimensions of 100 mm in diameter and 0.5 mm thick.

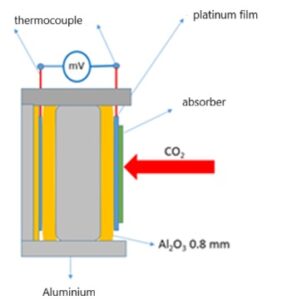

Deposition of platinum electrodes-The active element that absorbs the laser radiation is fixed on a platinum film with good thermal conductivity, for efficient heat transfer to the thermocouple (hot source). The platinum film is deposited on a thermal insulating element.

Activity 1.3 (Apel Laser partner) - Establishing the mechanical and electronic design requirements of the device.

Infrared laser radiation detectors based on infrared radiation-absorbing structures. The absorption of radiation is converted into heat due to interaction with the phonons of the absorbing materials. To measure the heat of these detectors, three aspects are taken into account:

a) Uniform dispersion throughout the entire absorbent volume

b) Heat transfer to the thermocouple

c) The rate of transfer of this heat

Activity 1.4 (partner Apel Laser) - Design, manufacture and testing of the mechanical and electronic parts of the energy meter.

Dr. Silviu Polosan, PhD

Senior Researcher I

National Institute of Materials Physiscs

Functional Nanostructures Laboratory

Tel: +40-(0)21-2418 268

email: silv@infim.ro

PROJECTS/ NATIONAL PROJECTS

Copyright © 2026 National Institute of Materials Physics. All Rights Reserved