MgB2 based superconducting composite materials: processing and shaping aspects for different magnetic applications

Project Director: Dr. Mihai BURDUSEL

Project ID: PN-III-P1-1.1-PD-2019-0651

Contract number: PD 139

Project acronym: SUPRASHAPE

Funded by: Romanian National Authority for Scientific Research, UEFISCDI

Contractor: National Institute of Materials Physics (NIMP)

Status: In progress

Start date: 04/08/2020

End date: 01/08/2022

Abstract:

The project proposes the manufacture of nanostructured superconducting composites as solid bodies (bulks) with diverse shapes/geometries, obtained from MgB2 powders with different additions, for magnetic shielding and energy storage applications. The aim is also to improve the critical functional parameters, such as critical current density and irreversibility magnetic field, but also to obtain complex shapes directly from the sintering process or through mechanical processing. Innovative solutions are proposed and explored, starting from process-properties-shape correlations, vortex pinning details (from advanced magnetic measurements), but also details on the functional properties, such as trapped magnetic field and shielding factor (from magnetic measurements and Hall sensors) depending on the obtained shapes. The final aim of the project is to obtain a reliable model for the production of complex shapes of the MgB2 ceramic material, competitive in terms of its implementation and commercialization for various magnetic applications (shielding, storage, levitation).

Project objective: The main objective of this project is to obtain through the SPS technique new superconducting composite materials based on MgB2 in various geometric shapes, in order to facilitate the implementation of this material into devices/applications.

Estimated results: Will be developed new bulks superconducting composite materials based on MgB2, which will have improved superconducting functional properties, but also the possibility to be obtained with various geometric shapes directly from the sintering process or by mechanical processing. With such an approach, it will be possible to develop new devices/applications/technologies, especially for magnetic shielding and energy storage, where this superconducting material, MgB2, has proven its potential in these directions. The results of this study may be disseminated through presentations at conferences or through publication in the form of a scientific article, book chapter, or patent.

Project director: Dr. Mihail Burdusel

Mentor: Dr. Lucica Miu

The project proposed the manufacture of superconducting composites in the form of solid bodies with various shapes/geometries, obtained from pure MgB2 powder or with various additions, for applications in shielding and/or storing magnetic energy. Dense composite solid bodies were obtained by sintering (spark plasma sintering, SPS). The composites were manufactured by:

(i) the addition of additives that allow mechanical processing such as BN-h or graphene;

(ii) the addition of some additions that modify the pinning force of the magnetic flux lines (B4C or Te and Ho2O3);

(iii) encapsulation by SPS in recycled PET or HDPE foils from packaging between which MgB2 is inserted. (Fig.1)

Fig. 1 Samples obtained by an encapsulation process between two polymeric foils of PET type polymer using the SPS method: II – MgB2 powder encapsulated between two polymeric foils; III – MgB2 strip encapsulated between two polymer foils.

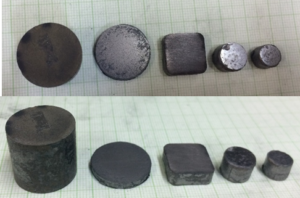

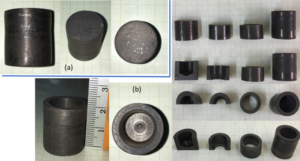

The parts from these composites have different shapes obtained directly from SPS processing using moulds with different geometries (Fig. 2) or by mechanical processing of the sintered solid bodies in case MgB2 contains additions (BN-h or graphene) that allows changing the shape by chipping (Fig. 3). MgB2 - BN-h composite parts with cylindrical or cup shape, individually or placed in the centre of a Fe ARMCO ferromagnetic ring (hybrid magnetic system) were tested and their high potential was demonstrated to be used as a magnetic shield with shielding efficiency when the external magnetic field is applied axially with the cylinder axis or perpendicular to it. The results open new possibilities for magnetic shielding, levitation and magnetic storage applications needed in different industries. The results were published in the prestigious ISI journals Scientific Reports and Superconductor Science & Technology, they were the subject of a national patent application whose idea, presented at Pro Invent, was awarded with two gold medals and 3 diplomas of excellence.

Fig. 1. MgB2 samples obtained by sintering.

Fig. 2. MgB2 samples obtained by sintering and mechanical processing.

Dr. Mihail Burdusel

Scientific Researcher III

PROJECTS/ NATIONAL PROJECTS

Copyright © 2025 National Institute of Materials Physics. All Rights Reserved