3D direct ink writing (robocasting) of bioceramic porous scaffolds: towards a new generation of bone graft substitutes (ROBONEGRAFT)

Project Director: Dr. George STAN

Project ID: PN-III-P1-1.1-TE-2019-0463

Project Director: Dr. George Stan

Project Type: National

Project Program: HUMAN RESOURCES, Young Teams

Funded by: Romanian National Authority for Scientific Research, UEFISCDI

Contractor: National Institute of Materials Physics

Project Status: Finished

Start Date: 1 January, 2021

End Date: 30 December, 2022

Project summary:

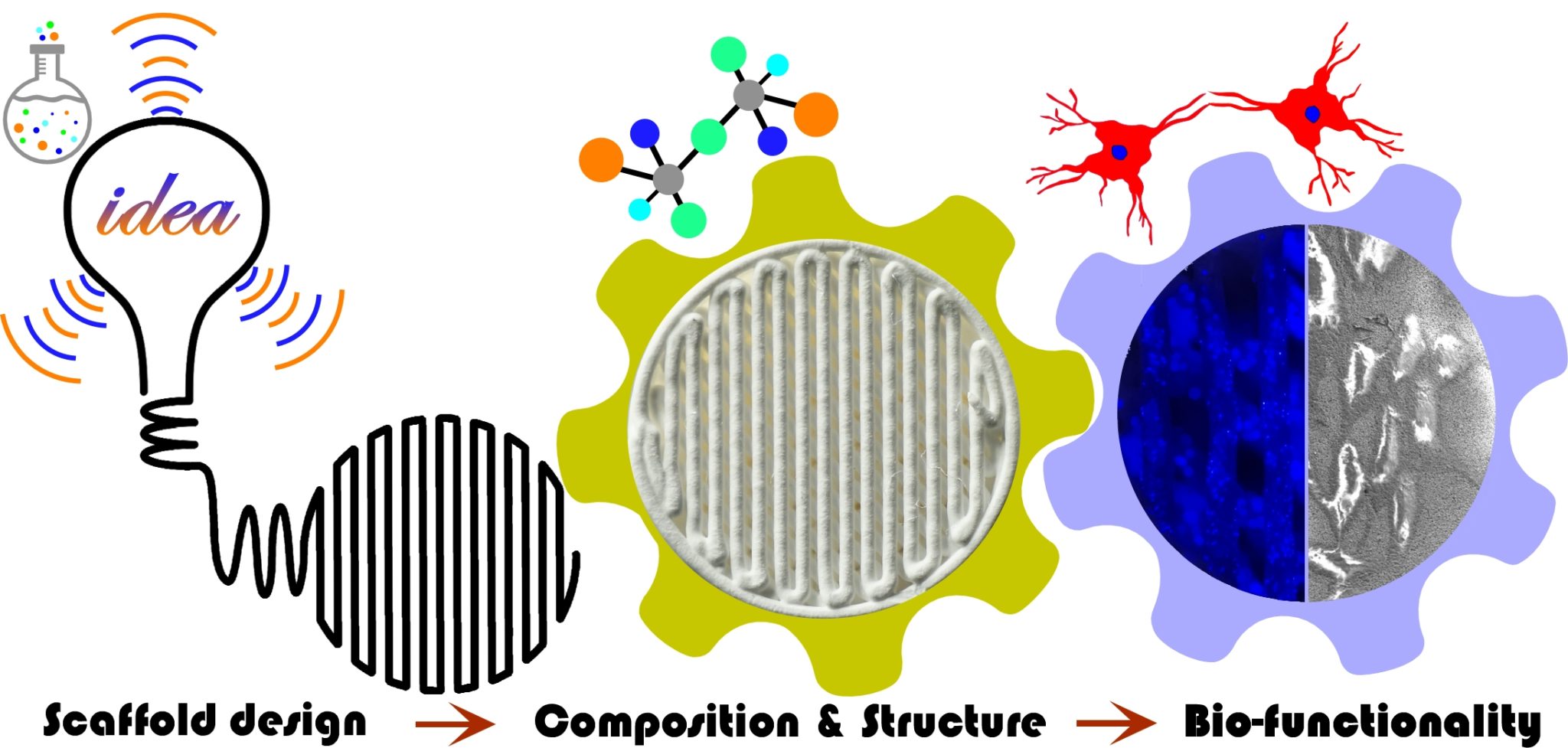

Bone transplantation demand stems from tissue deficiency or a substantial skeletal loss, and has multiple causes: age, severe trauma, chronical bone disorders/infections, tumor resections, congenital bone defects. Bone grafting evolved in the last decade into a distinct biomedical segment, which will continuously expand. Responding to this necessity, the project proposal aims to delineate series of innovative architectural solutions of porous bone graft substitutes (BGSs) to be fabricated by accessible and performant 3D robocasting technologies, from bioactive and/or piezoelectric ceramics. Their functional performance will be assessed to prospect their potential for developing a new generation of BGSs capable to satisfy the mechanical and biological requirements of both trabecular and the more demanding cortical bone regions. New routes for endowing angiogenesis, osteogenesis and antibacterial capabilities to both the bioactive and piezoceramic BGSs, such as to enable their rapid, safe and long-lasting osseointegration, will be explored and implemented. Not least the proposal will tackle another highly important issue: the lack of standard in vitro protocols for uniform cell seeding of porous scaffolds.

Innovative and original fundamental and technological elements are expected to emerge: (a) design of bioactive ceramics with controlled degradability and therapeutic ion release, (b) coupling of mechanical strong piezoelectric ceramics with biofunctional materials and (c) in vitro testing of piezoelectric effect on cells behavior under dynamical mechanical stress conditions. The project will lead to the creation of an independent research team of young scientists with complementary skills, and strive to (i) attract human resources in the national research; (ii) create opportunities of professional formation for young researchers, and (iii) generate premises for the future formation of a larger scientific community with skills and knowledge in materials for medicine.

Project Objectives:

General Objective: Opening New Perspectives Towards a New Generation of Ceramic Bone Graft Substitutes Based on Bioactive and Piezoelectric Ceramics

Specific objectives:

O1: Synthesis of alkali-free silica-based bioactive glass (SBG), calcium phosphates (CaP) and piezoelectric ceramic powders by melt-quenching, co-precipitation, and conventional ceramic technology (solid-state)/hydrothermal synthesis, respectively. – Realized [RST 1/2021].

O2: Electing the most promising bioactive and piezoelectric ceramics for 3D printing based on multi-parametrical structural, piezoelectric, surface energy, mechanical and in vitro biological evaluations. – Realized [RST 1/2021].

O3: Fabrication of 3D bioactive and/or piezoelectric bone graft substitutes by robocasting with different filament distribution geometries and pore sizes. – Realized [RST 1 & 2/2021-2022].

O4: Exploratory studies of coating the 3D porous bone substitutes constructs based on piezoelectric ceramics with sacrificial bio-functional layers by chemical and physical deposition techniques. – Realized [RST 2/2022].

O5: Cross-examination of the physical-chemical, mechanical and bio-functional features of the fabricated porous scaffolds by multi-parametric analyses. – Realized [RST 2/2022].

O6: Rational selection of the best scaffold designs dedicated to bone substitution, ensuring a functional compromise between porosity, biofunctionality and mechanical performance. – Realized [RST 2/2022].

O7: Consolidation and strengthening of the research team by addition of young researchers with complementary skills and active interests in field of 3D printing and/or bone regeneration prospective solutions, and creation of an independent research program. Dissemination of relevant scientific results. – Realized [RST 1 & 2/2021-2022].

- Dr. George Stan, PhD in Materials Engineering since 2011 - Project director (https://www.webofscience.com/wos/author/rid/B-5690-2011);

- Dr. Adrian-Claudiu Popa, PhD in Medicine (Cellular and Molecular Medicine) since 2015 - Team member (https://www.webofscience.com/wos/author/rid/K-4606-2012);

- Dr. Cristina Besleaga Stan, PhD in Physics since 2013 - Team member (https://www.webofscience.com/wos/author/rid/I-7862-2019);

- Dr. Alexandru Evanghelidis, PhD in Physics since 2018 - Team member (https://www.webofscience.com/wos/author/rid/AAA-1954-2019);

- PhD student Andrei Tomulescu, chemist - Team member (https://www.webofscience.com/wos/author/rid/B-8700-2019);

- PhD student Maria-Iuliana Chirica (Bogdan), chemist - Team member (https://www.webofscience.com/wos/author/rid/AAA-2636-2019);

- Dr. Luminita Amarande, PhD in Physics since 2003 - Team member (https://www.webofscience.com/wos/author/rid/B-7800-2011);

- 1 vacant position occupied by Dr. Liliana Marinela Balescu, PhD in Physics since 2016 (https://www.webofscience.com/wos/author/rid/E-7100-2014).

The ROBONEGRAFT project (contract TE135/2020) (1) aimed and successfully achieved the incremental and integral completion of the idea – to the synthetic bone graft substitute demonstrator stages, starting from the delineation of methods for the preparation of a wide range of materials (biocompatible piezoelectric ceramics, simple, binary and ternary calcium phosphates, (based on hydroxyapatite, β- and/or α-tricalcium phosphate) pure or doped and phosphate- and silica-based bioactive glasses) and the selection of the most promising materials based on multi-parametric evaluations (complex physico-chemical using advanced investigation methods, mechanical and biological in vitro), to the optimization of ceramic pastes with appropriate pseudoplastic properties and the successful manufacture and testing of the first demonstrators at the national level of macro-porous synthetic bone graft substitutes (from bioactive or piezoelectric materials) by the robocasting technology, AND (2) allow to coagulate a dynamic young team with complementary inter-disciplinary expertise, able and willing to continue the scientific and technological advances in this field. These, we consider, are the most significant results of the TE135 project (in full congruence with the TE Competition aims and scopes), beyond any reached scientific dissemination milestone. Thus, the TE135 project allowed the opening of a new research theme at the national level and the training of human resources capable now of achieving scientific and technological progresses, relevant at international level.

Stage I summary:

Project PN-III-P1-1.1-TE-2019-0463 (contract TE135/2020) aims to open perspectives for the realization of a new generation of synthetic bone graft substitutes (scaffolds) based on bioactive and piezoelectric ceramics. Starting from this general objective, Stage I of the PN-III-P1-1.1-TE-2019-0463 (2021.01.01 - 2021.12.31) research project was dedicated to both (1) the preparation, characterization and selection of future source materials [e.g., silicate and phosphate bioactive glasses, doped with Zn, Sr, Cu and/or Ga, synthesized by the melt-quenching; piezoelectric ceramics (based on: KNbO3; LiNbO3; LiTaO3; BaTiO3 simple and doped with Zr; and solid solutions from the Ba(Ti0.8Zr0.2)TiO3 – (Ba0.7Ca0.3)TiO3) binary system manufactured by the solid-state reaction conventional ceramic technology; simple, binary and ternary calcium phosphates, doped with Mn, Sr, Mg and/or Ga, prepared by co-precipitation/hydrothermal synthesis or derived from biological and mineral resources] for either scaffolds and/or bioactive functionalization layers, and (2) the first experiments of 3D printing, using the robocasting technology (direct ink writing) – primary, and by incorporating agents porous (vegetable fibers, whose thermal combustion will generate micro- and macro-pores and inter-canaliculi) – secondarily, of macro-porous synthetic bone graft substitutes from the ceramic materials selected based on the multi-parametric physical-chemical and in vitro biological evaluations. Part of the results obtained in this stage of the project were disseminated by presentations at international conferences (1) and articles published in Web of Science®-indexed journals (4).

Delivered results:

- 1 study scientific study on the methods of synthesis of oxide-based source powder materials (bioactive ceramics and glasses, piezoelectric ceramics) to be employed for the further fabrication of bone graft substitutes by the robocasting printing technology;

- 1 presentation (poster type) held at the E-MRS 2021 Fall Meeting international conference;

- 4 articles published in journals indexed in Web of Science®, two situated in the Q2 quartile and two in the Q1 quartile.

The scientific report cannot be yet divulged on the project website, as the results are in the process of being published, but it can be accessed upon request at UEFISCDI.

2021: THE SYNTHETIC SCIENTIFIC REPORT no. 1 in .pdf format is available at UEFISCDI, and can be accessed by request.

Stage II summary:

Stage II of the project was devoted to the manufacture by robocasting technology of macro-porous scaffolds, based on bioactive materials (i.e., biphasic calcium phosphate doped with Sr and Sr/Mg) and piezoelectric (BCTZ50), selected following multi-parametric evaluations (physico-chemical, mechanical and biological in vitro), having different shapes and filament distribution geometries. In this scope, a special attention was focused on both the preparation of ceramic pastes with appropriate shear-thinning properties and to the definition of experimental protocols for the uniform cellular colonization of macro-porous constructs, as well as to carry out exploratory the selecting adequate architectural models of synthetic bone graft substitutes, followed by multi-parametric comparative characterizations to probe their functional potential. Part of the results of Stage II of the project were already disseminated by three scientific communications at international events, three articles published in Web of Science® indexed journals (another two are currently submitted for evaluation, and two more are in preparation), and an OSIM patent application.

Delivered results:

- 2 ceramic paste recipes for robocasting 3D printing based on bioactive materials and piezoelectric ceramics;

- 2 methods for the surface functionalization of 3D scaffolds based on magnetron sputtering and dip-coating technologies;

- batches of macro-porous scaffolds based on bioactive and piezoelectric materials with different shapes and filament distribution geometries;

- 3 articles published in Web of Science® journals, one situated in the Q2 quartile and two in the Q1 quartile;

- 2 articles submitted for evaluation in Web of Science® journals situated in the Q1 quartile;

- 3 scientific communications at international conferences/workshops;

- 1 OSIM patent application.

The scientific report cannot be yet divulged on the project website, as the results are in the process of being published or in the process of being patented, but it can be accessed upon request at UEFISCDI.

2022: THE FINAL SCIENTIFIC in .pdf format is available at UEFISCDI, and can be accessed by request.

- 2021: Ioana Cristina Tudor, student, 2nd year of study, Faculty of Medical Engineering, University Politehnica of Bucharest, effectuated 360 hours of scientific practice in the field of synthesis and physical-chemical and in vitro biological characterization of ceramic materials in both bulk and thin film forms, under the coordination of Dr. George Stan (Project director of TE135/2021).

Web of Science® articles:

- 01. A.C. Mocanu, F. Miculescu*, G.E. Stan^, R.C. Ciocoiu, M.C. Corobea, M. Miculescu, L.T. Ciocan, Preliminary studies on graphene-reinforced 3D products obtained by the one-stage sacrificial template method for bone reconstruction applications; J FUNCT BIOMATER 12 (2021) 13. https://doi.org/10.3390/jfb12010013.

- 02. A.C. Mocanu, F. Miculescu*, G.E. Stan^, A.M. Pandele, M.A. Pop, R.C. Ciocoiu, S.I. Voicu, L.T. Ciocan, Fiber-templated 3D calcium-phosphate scaffolds for biomedical applications: The role of the thermal treatment ambient on physico-chemical properties; MATERIALS 14 (2021) 2198. https://doi.org/10.3390/ma14092198.

- 03. I.M. Chirica^, A.M. Enciu, T. Tite*, M. Dudau, L. Albulescu, S.I. Iconaru, D. Predoi, I. Pasuk, M. Enculescu, C. Radu, C. Mihalcea, A.C. Popa^, N. Rusu, S. Nita, C. Tanase*, G.E. Stan*,^, The physico-chemical properties and exploratory real-time cell analysis of hydroxyapatite nanopowders substituted with Ce, Mg, Sr and Zn (0.5–5 at.%); MATERIALS 14 (2021) 3808. https://doi.org/10.3390/ma14143808.

- 04. A. Gaddam*, A.A. Allu, S. Ganisetti, H.R. Fernandes, G.E. Stan^, C.C. Negrila, A.P. Jamale, F. Mear, L. Montagne, J.M.F. Ferreira; Effect of vanadium oxide on the structure and Li-Ion conductivity of lithium silicate glasses; J PHYS CHEM C 125 (2021) 16843. https://doi.org/10.1021/acs.jpcc.1c05059

- 05. B.W. Stuart*, G.E. Stan^, A.C. Popa^, M.J. Carrington, I. Zgura, M. Necsulescu, D.M. Grant*, New solutions for combatting implant bacterial infection based on silver nano-dispersed and gallium incorporated phosphate bioactive glass sputtered films: A preliminary study; BIOACTIVE MATER 8 (2022) 325. https://doi.org/10.1016/j.bioactmat.2021.05.055.

- 06. T. Tite, A.C. Popa^, B.W. Stuart, H.R. Fernandes, I.M. Chirica^, G.A. Lungu, D. Macovei, C. Bartha, L. Albulescu, C. Tanase, S. Nita, N. Rusu, D.M. Grant, J.M.F. Ferreira, G.E. Stan*,^, Independent and complementary bio-functional effects of CuO and Ga2O3 incorporated as therapeutic agents in silica- and phosphate-based bioactive glasses; J MATERIOMICS 8 (2022) 893. https://doi.org/10.1016/j.jmat.2021.12.009.

- 07. C. Besleaga^, B. Nan , A.C. Popa^, L.M. Balescu^, L. Nedelcu, A.S. Neto, I. Pasuk, L. Leonat, G. Popescu-Pelin, J.M.F. Ferreira, G.E. Stan*,^, Sr and Mg doped bi-phasic calcium phosphate macroporous bone graft substitutes fabricated by robocasting: A structural and cytocompatibility assessment; J FUNCT BIOMATER 13 (2022) 123. https://doi.org/10.3390/jfb13030123.

- 08. L. Nedelcu, J.M.F. Ferreira, A.C. Popa^, L. Amarande^, B. Nan, L.M. Balescu^, C.D. Geambasu, M. Cioangher, L. Leonat, M. Grigoroscuta, D. Cristea, H. Stroescu, R.C. Ciocoiu, G.E. Stan^,*, Multi-parametric exploration of a selection of piezoceramic materials for cortical bone graft substitutes application; MATERIALS 16 (2023) 901. https://doi.org/10.3390/ma16030901.

OSIM Patent application:

- 01. A.R. Iuga, A.C. Popa, V. Kuncser, N. Iacob, Device with permanent magnets capable to reduce the sedimentation speed of particles in a viscous medium; OSIM patent request no. A/00716/11.11.2022.

International Conferences:

- 01. T. Tite, A.C. Popa^, I.M. Chirica^, B.W. Stuart, A.C. Galca, L.M. Balescu, G. Popescu-Pelin, D.M. Grant, J.M.F. Ferreira, G.E. Stan^, Tuning the cross-area uniformity, structure and biological response of sputtered phosphate bioglass films by the gas pressure; E-MRS 2021 Fall Meeting, Symposium J: „Materials and technological solutions preventing biofilms and antimicrobial resistance”, 20–23 September 2021 (poster).

- 02. L.M. Balescu^, C. Besleaga^, B. Nan, A.C. Popa^, L. Nedelcu, A.S. Neto, I. Pasuk, L. Leonat, G. Popescu-Pelin, J.M.F. Ferreira, G.E. Stan^, Strontium and/or Magnesium substituted biphasic calcium phosphate-based scaffolds for bone graft applications; IBWAP 2022 – Section 4: Cross-disciplinary application of physics, 12–15 July 2022 (poster).

- 03. L. Amarande^, L. Nedelcu, M. Cioangher, L. Leonat, M. Grigoroscuta, L.M. Balescu^, C. Besleaga^, C. Ciobotaru, A.C. Popa^, G.E. Stan^, H. Stroescu, B. Nan, J.M.F. Ferreira, Synthesis and characterization of piezoceramic materials for robocasting printing of 3D porous scaffolds; IBWAP 2022 – Section 4: Cross-disciplinary application of physics, 12–15 July 2022 (poster) - 2nd prize.

- 04. G.E. Stan^, T. Tite, A.C. Popa^, B.W. Stuart, H.R. Fernandes, M.I. Chirica^, G.A. Lungu, D. Macovei, L. Albulescu, C. Tanase, S. Nita, N. Rusu, D.M. Grant, J.M.F. Ferreira, Single and coupled bio-functional effects of CuO and Ga2O3 incorporated as therapeutic agents in silica- and phosphate-based bioactive glasses; IBWAP 2022 – Section 4: Cross-disciplinary application of physics, 12–15 July 2022 (oral presentation).

*corresponding author

^project team member

GEORGE E. STAN, PhD in Materials Engineering

Senior Researcher I

Telephone: +40-(0)21-2418 128 or +40-(0)21-2418 153

Department: Laboratory of Multifunctional Materials and Structures

PROJECTS/ NATIONAL PROJECTS

Copyright © 2025 National Institute of Materials Physics. All Rights Reserved